The de-coating of carbon based coatings is difficult and imbedding the risk of over etching the surfaces. Carbotec has significantly improved this technic.

Coating adhesion

measured with Rc indent 150kg

Coating stack

Calo-grinding of a Carbotec DLC / DLN LS coating

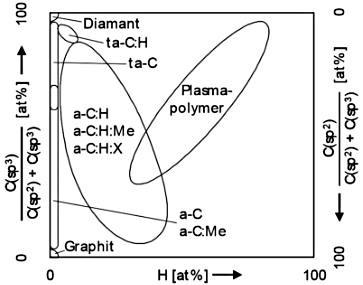

Coating structure (…the smooth difference)

Scanning electron microscope (SEM) pictures of coating fracture

Coating friction

Ball-on-Disc test to evaluate coefficient of friction (COF)

| DLC | DLN LS | DLN LF | DLC/DLN LS | DLC/DLN LF | |

|---|---|---|---|---|---|

| Hardness HV0.05 | 3.000 HV | 1.300 HV | 1.800 HV | 3.000 HV | 3.000 HV |

| Friction (vs. 100Cr6) | 0.1-0.15 | 0.15 | 0.03-0.05 | 0.15 | 0.03-0.05 |

| Thickness | 2-3µm | 2-3µm | 2-3µm | 2-3µm | 2-3µm |

| Prozesstemperature | 200°C | 200°C | 200°C | 200°C | 200°C |

| Applicationtemperature | 300°C | 400°C | 400°C | 300°C | 300°C |

| Colour | black | black | black | black | black |

Max substrate size: D 750 * 1.000mm

Max substrate weight: 500kg

You are currently viewing a placeholder content from Google reCAPTCHA. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information 'You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Turnstile. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information